Want a Rotary Tiller Blade?

TAIYO is the Answer.

We provide solution to any requirement based on 60 years of experience.

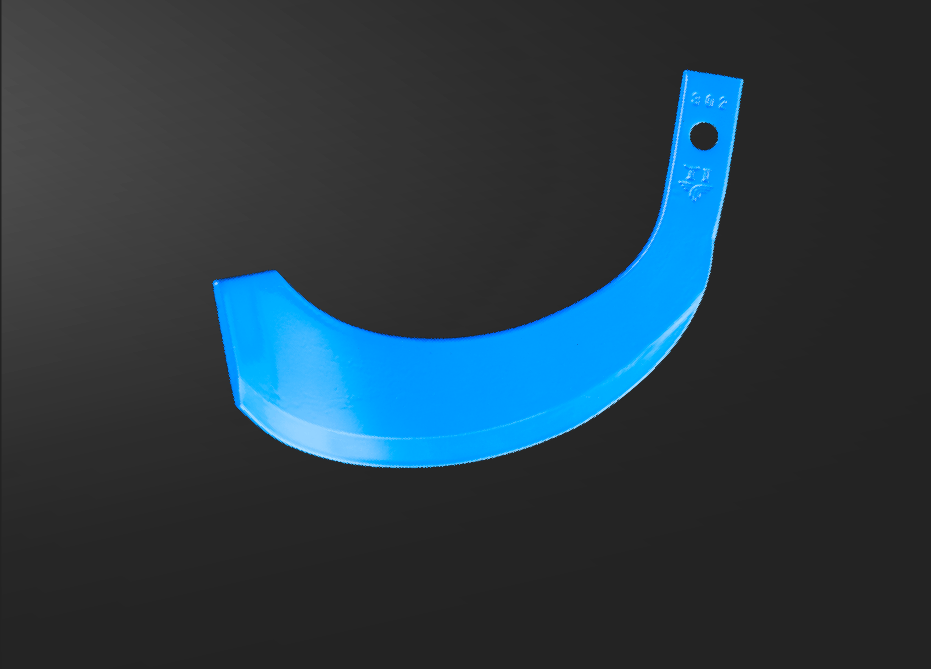

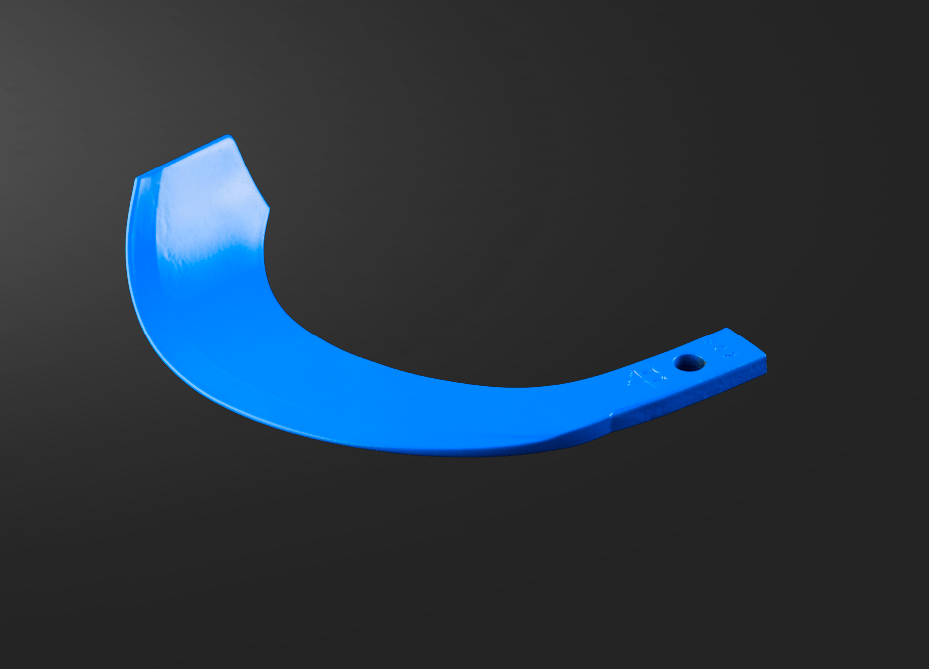

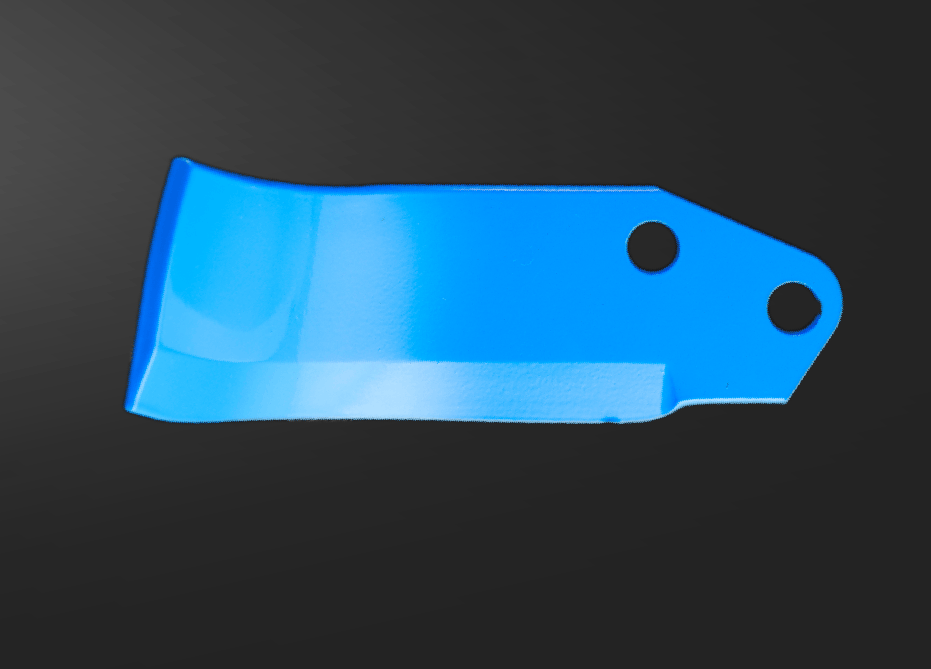

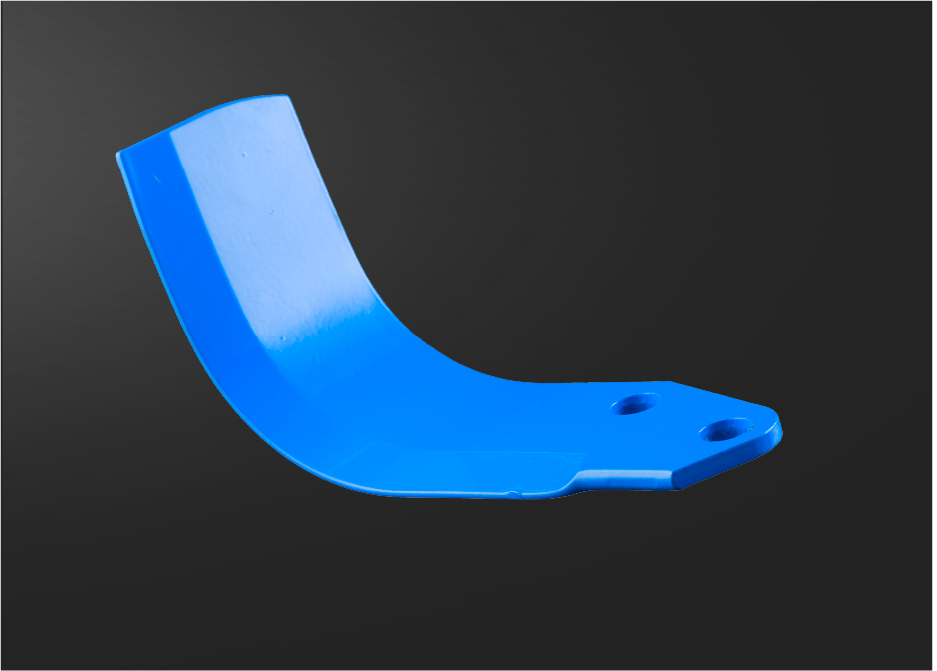

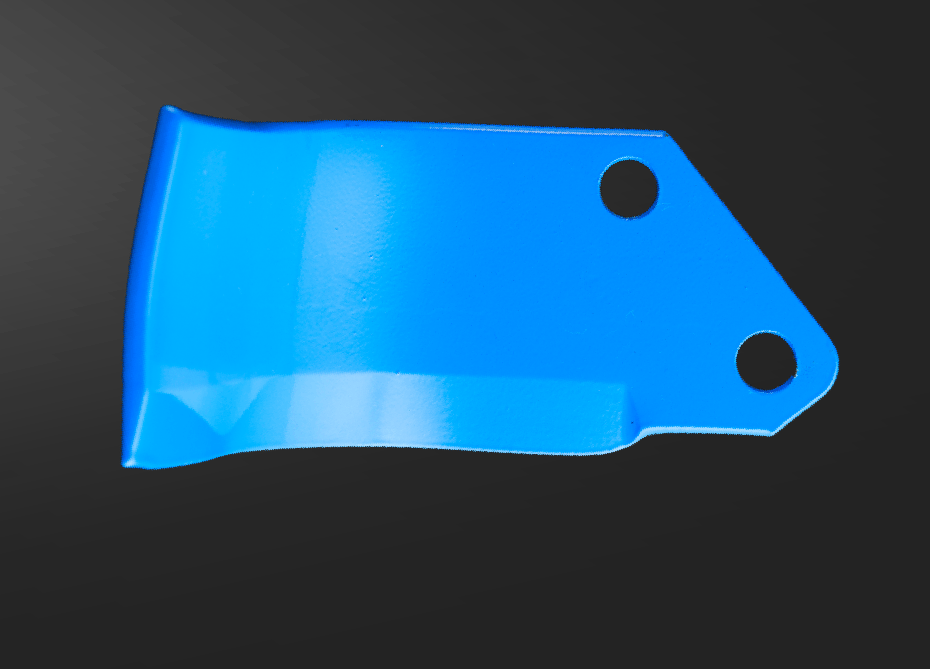

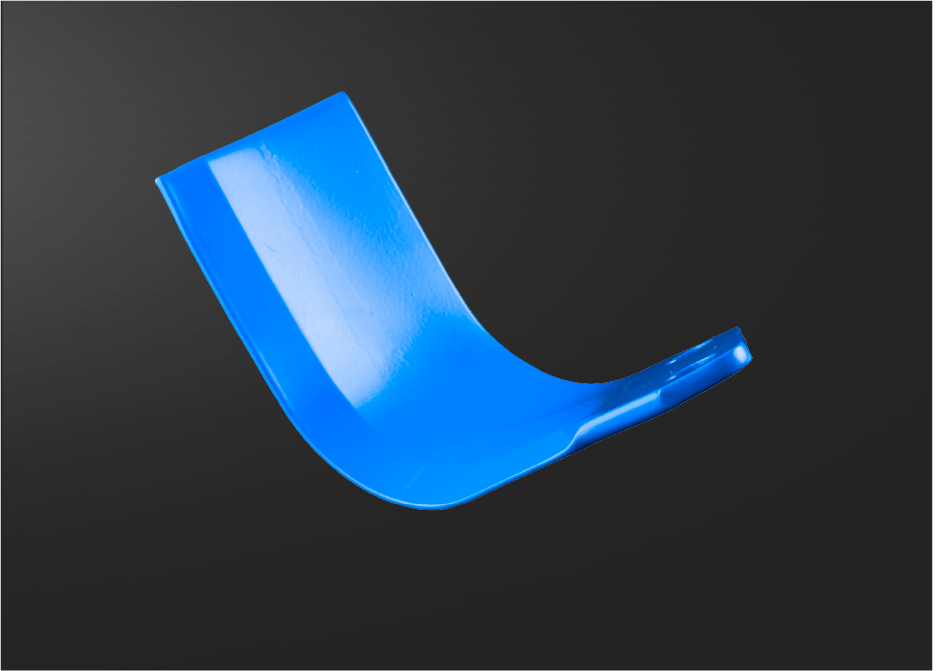

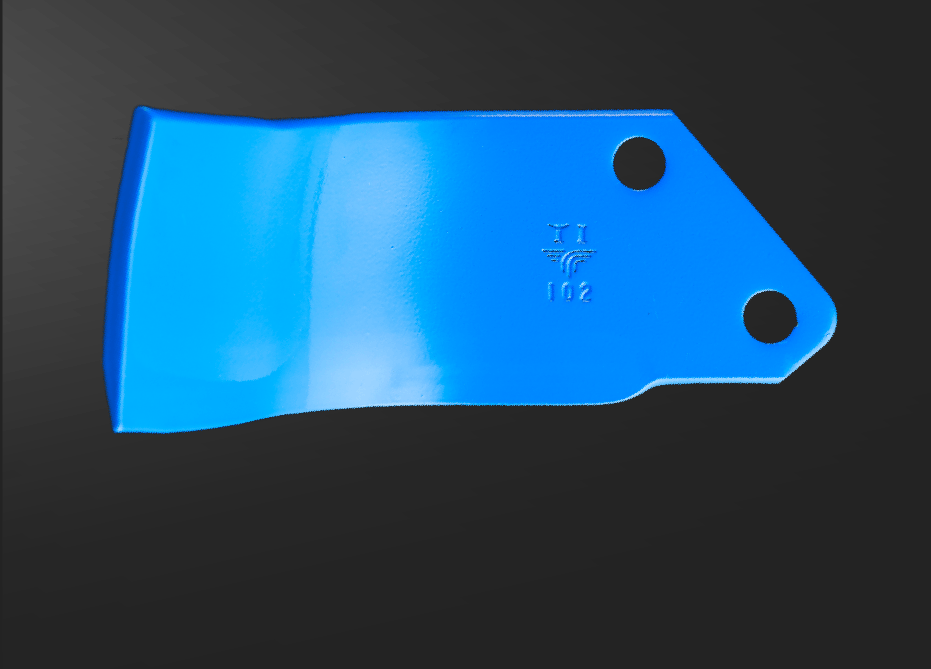

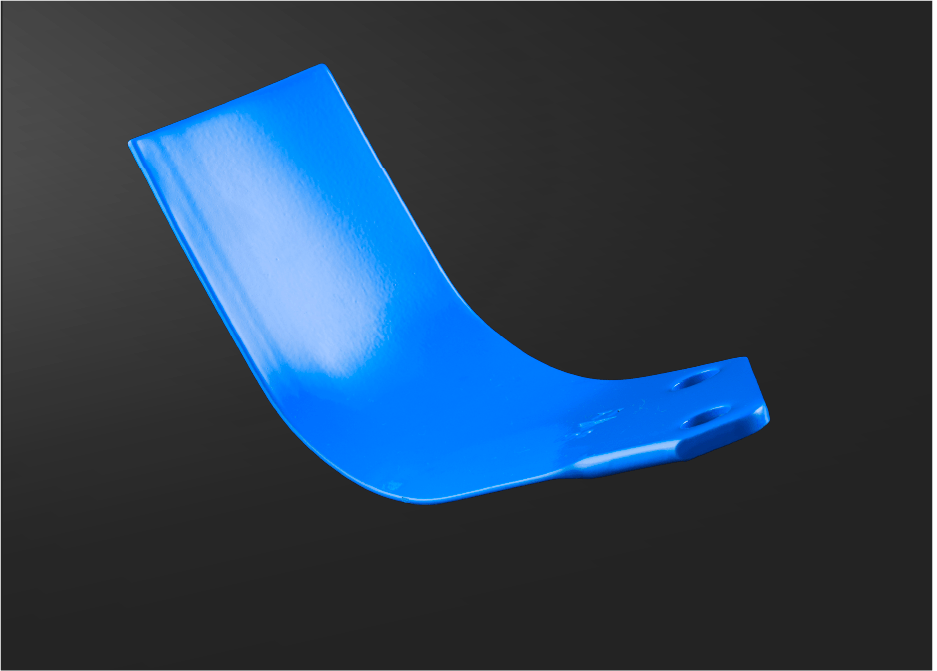

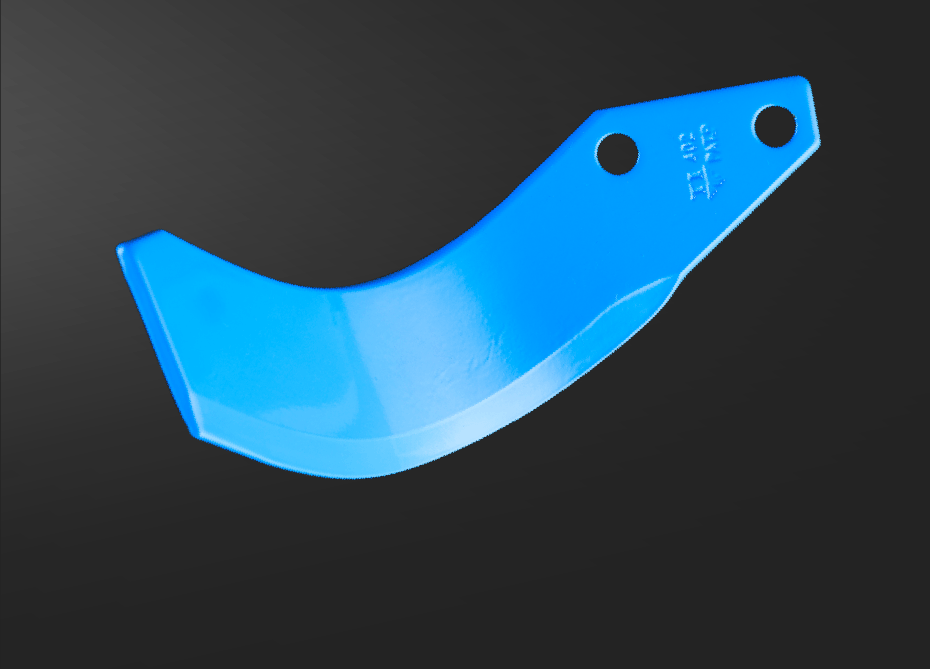

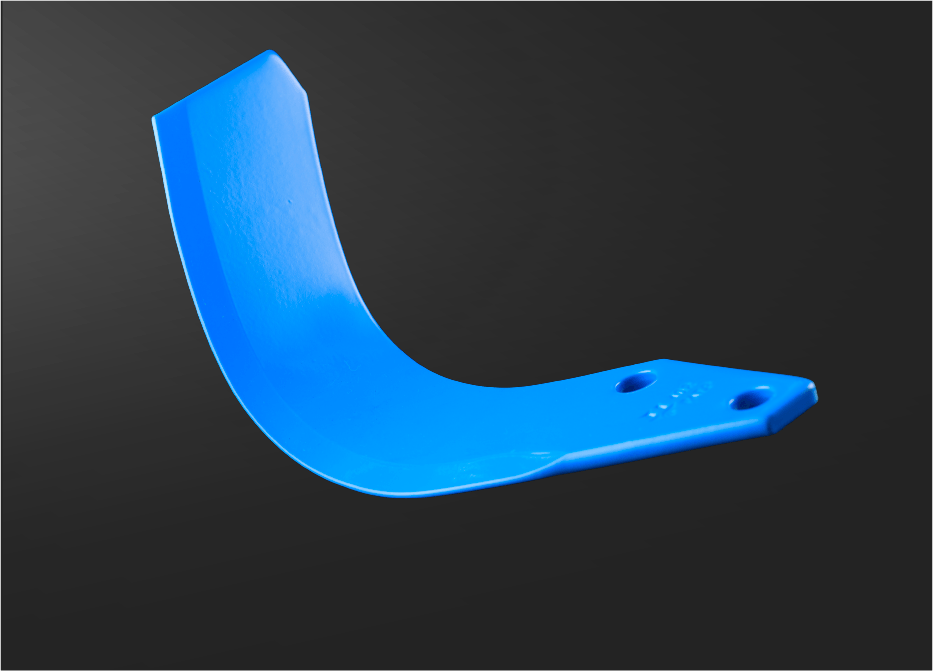

We make various types of blade such as J type, L type, LJF type, and C type.

Based on our original cultivate theory, we propose the best shape.

`One-Touch mechanism`, (obtained a patent in Japan) which shortens the time for blade exchange is an example of our persistent efforts for improvement.

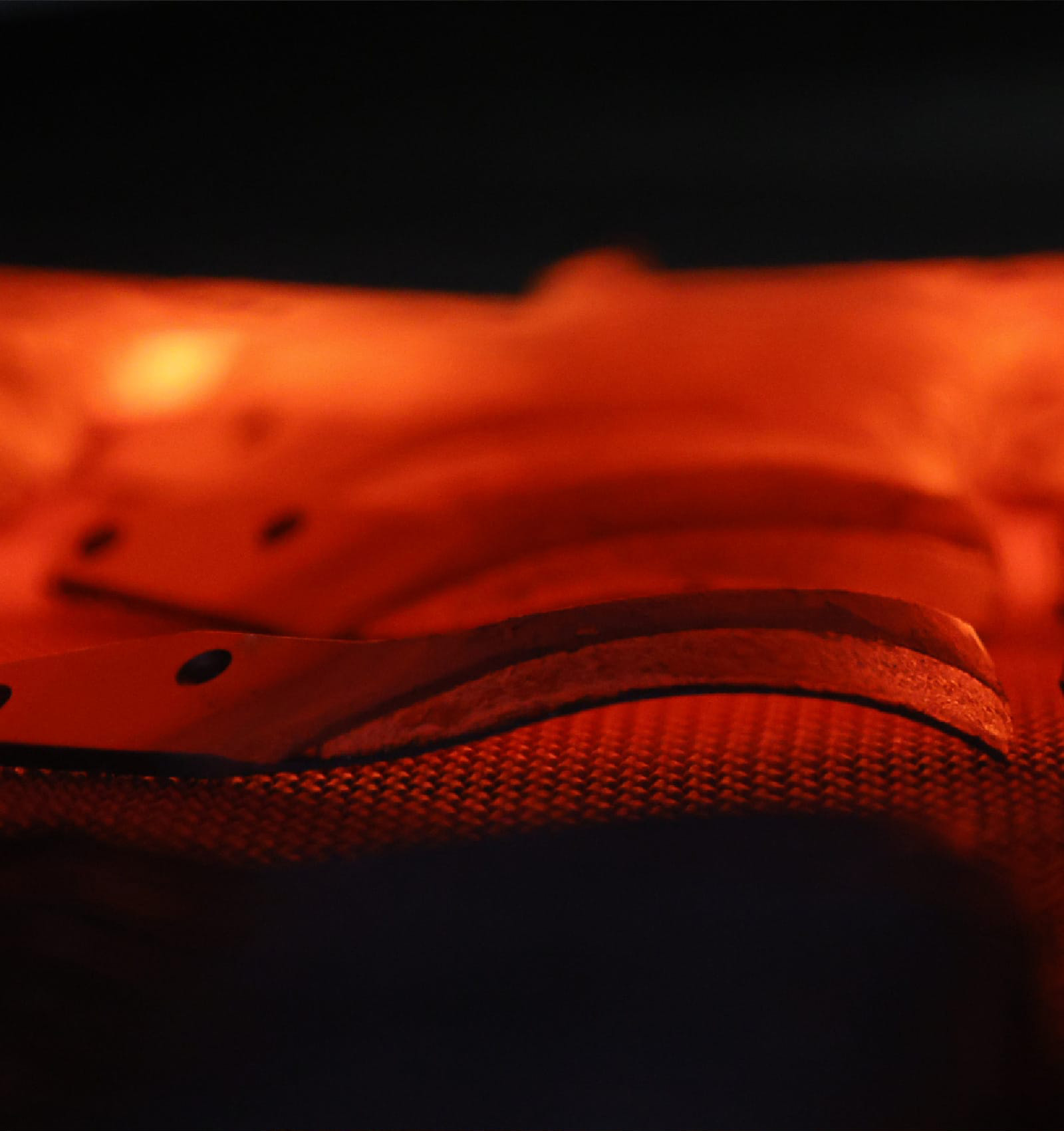

tough

Heat Treatment Technology for

the Ideal Hardness

We are absolutely confident in making steel hardness to the targeted value, because we have been doing heat treatment of special steel for many years. Cheaper blade without proper heat treatment is easy to break and bend, not having good durability.

beautiful

Welding a super hard alloy by

our original welding technology

After years of research, we have established the technology to weld a super hard alloy. This enables us to supply long-lasting high-end product which can deal with any type of sediment wear.

beautiful

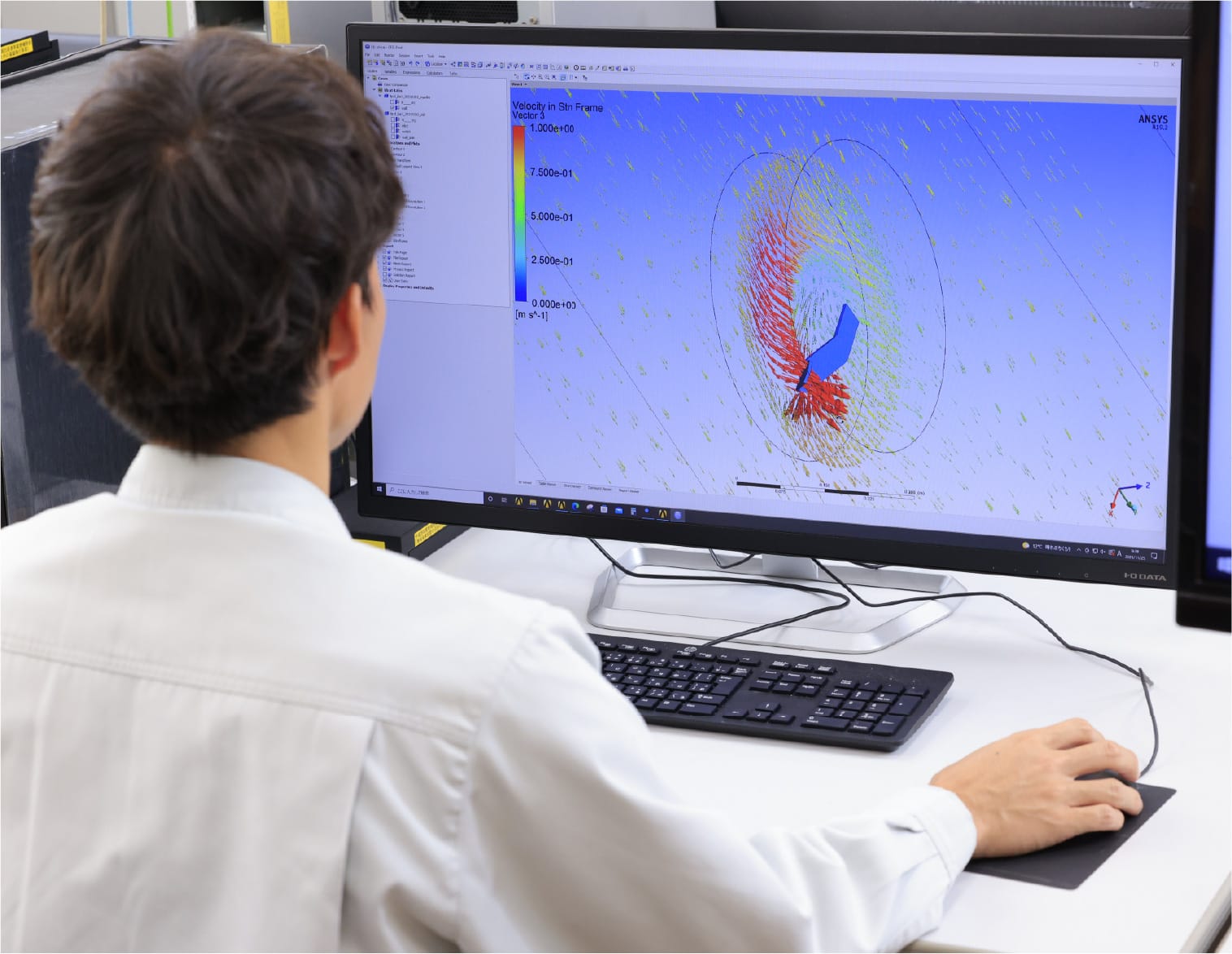

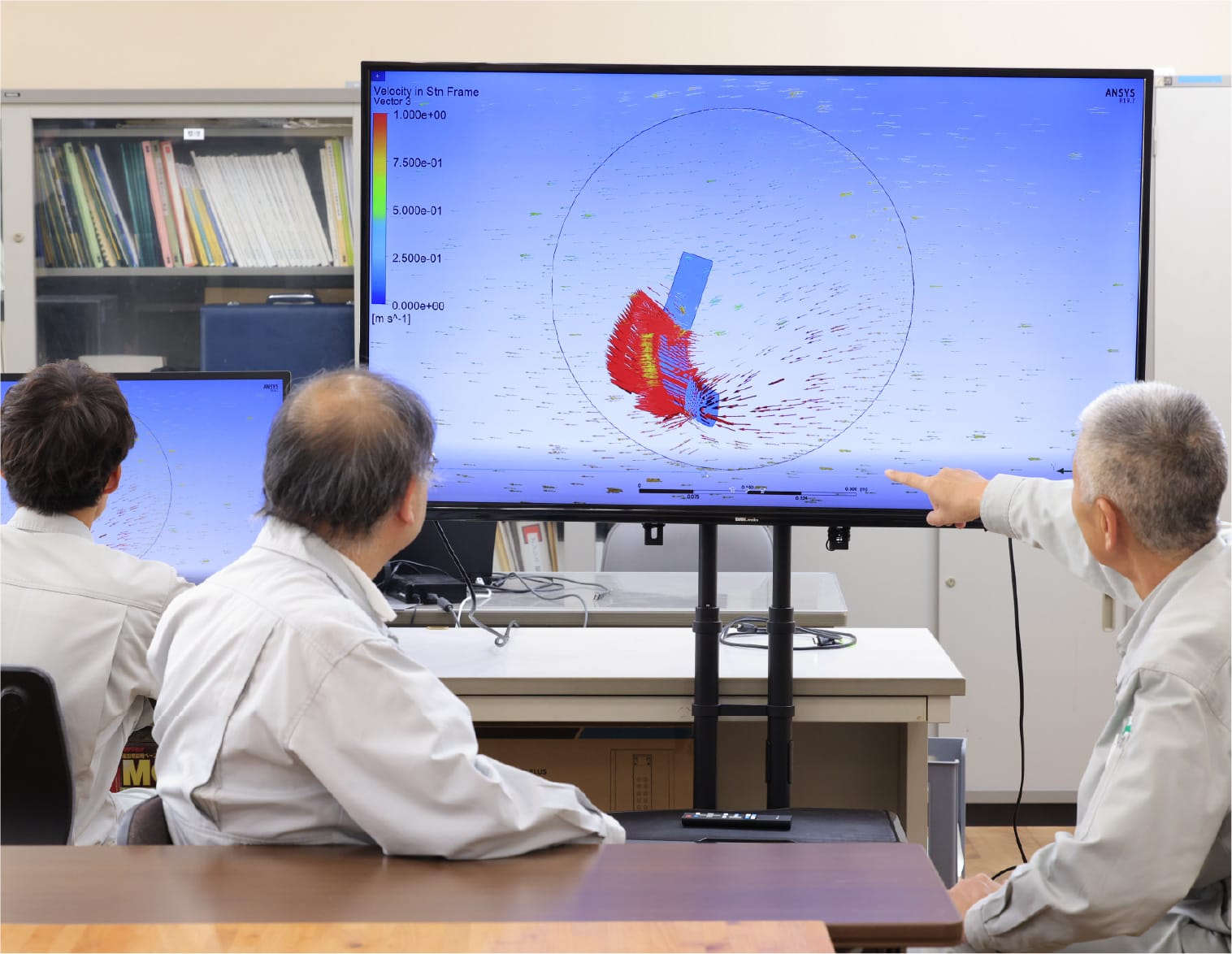

Analysis using 3D CAD &

Advanced design

By using state-of-the-art 3D CAD technology, we produce blade which suits to the operating environment. Taiyo`s blade overwhelms other brands in terms of its performance and durability, because we simulate and design based on the data accumulated through 60 years of experience.

quality

Quality

Japan Quality anywhere in the World

We inspect raw material every time it comes in to ensure the quality.

Quality of raw material used in our Japanese factory and Indian factory are the same.

Thorough Quality Control & High Quality Standards

We have been continuously working on quality control and as a result, we have achieved defect ratio less than 1000ppm in every production line.

Now, we are working on to achieve less than 500ppm.

We check hardness and size of blades to ensure there is no product that is out of our standard. Same process is done in our Indian factory to keep the same quality.

From 2 bases, Japan & India, to the World

As our annual production capacity (Japan + India) is 20 million blades, quick and flexible delivery is possible. If we can predict more sales in future, we will increase production capacity. Also, having a factory in India enables us to do quick delivery specially to South-East Asia.

contact

Contact

We welcome any inquiry about rotary tiller blades.

Specialist for the blades will reply.